The team General Motors and Ventec Life Systems assembled to help fight the COVID-19 pandemic delivered its 30,000th V+Pro critical care ventilator to the US Department of Health and Human Services on Aug 31, the companies announced.

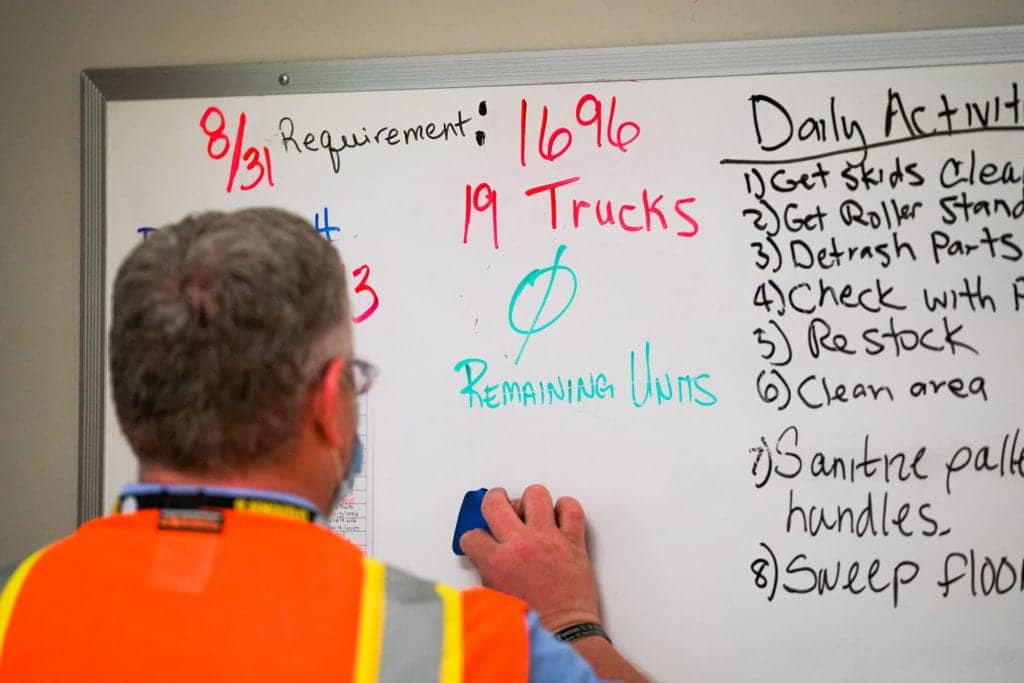

At the start of the COVID-19 pandemic, GM and Ventec collaborated to rapidly scale up production of critical care ventilators. In one month, the teams went from an introductory phone call to delivering life-saving technology to frontline medical heroes. The full federal order was completed in just 154 days, with one ventilator completed about every seven minutes.

With yesterday’s shipment, GM has formally turned over operational control of the company’s Kokomo ventilator manufacturing operation to Ventec. Ventec will produce VOCSN multi-function critical care ventilators in Kokomo, as well as in Bothell, Washington in response to ongoing demand during the pandemic. Ventec’s monthly ventilator production increased 80 times during the pandemic.

“Our drive to put critical care ventilators into production was fueled by thousands of people at GM, Ventec and our suppliers who all wanted to do their part to help save lives during the pandemic,” said Mary Barra, GM Chairman and CEO. “It was inspiring to see so many people achieve so much so quickly.”

“Our hope continues to be that mitigation efforts stop the spread of this virus. Ventec Life Systems is committed to maintaining increased production capacity for as long as it is needed to ensure frontline healthcare workers have the tools necessary to save lives,” said Ventec Life Systems CEO Chris Kiple. “We are incredibly proud of how our teams came together united by a common mission.”

One of the first medical facilities to receive a GM-Ventec ventilator was Weiss Memorial Hospital in Chicago.

“We are very grateful to Ventec Life Systems and General Motors for the critical care ventilators we received in April,” said Dr. Suzanne Pham, M.D., hospitalist at Weiss Memorial Hospital. “The devices built in just one month are currently helping patients battling COVID-19, and are valuable tools enabling our medical team to save lives. I’m proud to say we have had many patients beat COVID-19, wean off the ventilator and safely return home.”

One of those patients was Jeffrey Dickerson of Chicago: “I’m grateful that Weiss Memorial Hospital received ventilators created by Ventec Life Systems and General Motors,” he said. “When I was rushed into the hospital room, I couldn’t walk without pausing to catch my breath. The team at Weiss put me on one of your machines, and I was fortunate to make a fast recovery. They later told me they were running out of ventilators, but fortunately had received one of the first shipments from the federal government, so I didn’t have to wait for help.”

Many of the men and women who joined this historic effort to quickly ramp up ventilator production felt a strong call of duty to support their families, communities and country.

Glenn Sandifer, product assembler: “When I received information that Kokomo was hiring for its ventilator operations, I was homeschooling my niece. At first, I didn’t respond to the email. But it became apparent this was a historic moment and I wanted to do my part to help.”

Ian Cartier, robotic technician: “This team has worked so hard to accomplish this. Our commitment, our purpose to help those in need, is inspiring. It’s much deeper than simply hitting our goal. All of us chose to leave the security of our homes and give 110 percent every single day to build ventilators. We came in with the attitude that for every challenge we were handed that day, that we would face it, fix it and overcome it. That collective attitude has brought us to where we are today.”

J.C. Barnett, group leader: “We – GM and me, as an employee – have helped our country through rough times. I contributed. We contributed. We have done our part. And it was the right thing to do.”

Mike Schroeder, shift leader: “My family has been a part of the medical industry. My daughter is a physician assistant and my wife works for a blood center. But it wasn’t until GM started this project in late March that it hit home for me. The moment I saw our first shipment of critical care ventilators being received at the hospitals by the doctors and medical staff was the moment I realized the importance of what we were doing.”

Andy Chapman, mechanical engineer: “Some days I would get in at 6 a.m. and leave at 3 a.m., and we were working side by side with GM the entire time. Their skill and dedication were essential to successfully completing this mission.”

The unique collaboration between Ventec and GM to build V+Pro critical care ventilators began with conference calls initiated by stopthespread.org on March 17 and 18. The first units were delivered to Franciscan Health Olympia Fields in Olympia Fields, Illinois and Weiss Memorial Hospital in Chicago. A third shipment was delivered by UPS to the Gary/Chicago International Airport on April 18 for distribution to other locations where the need was greatest.